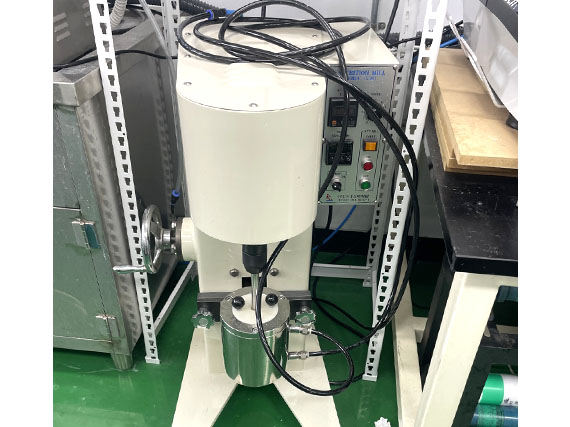

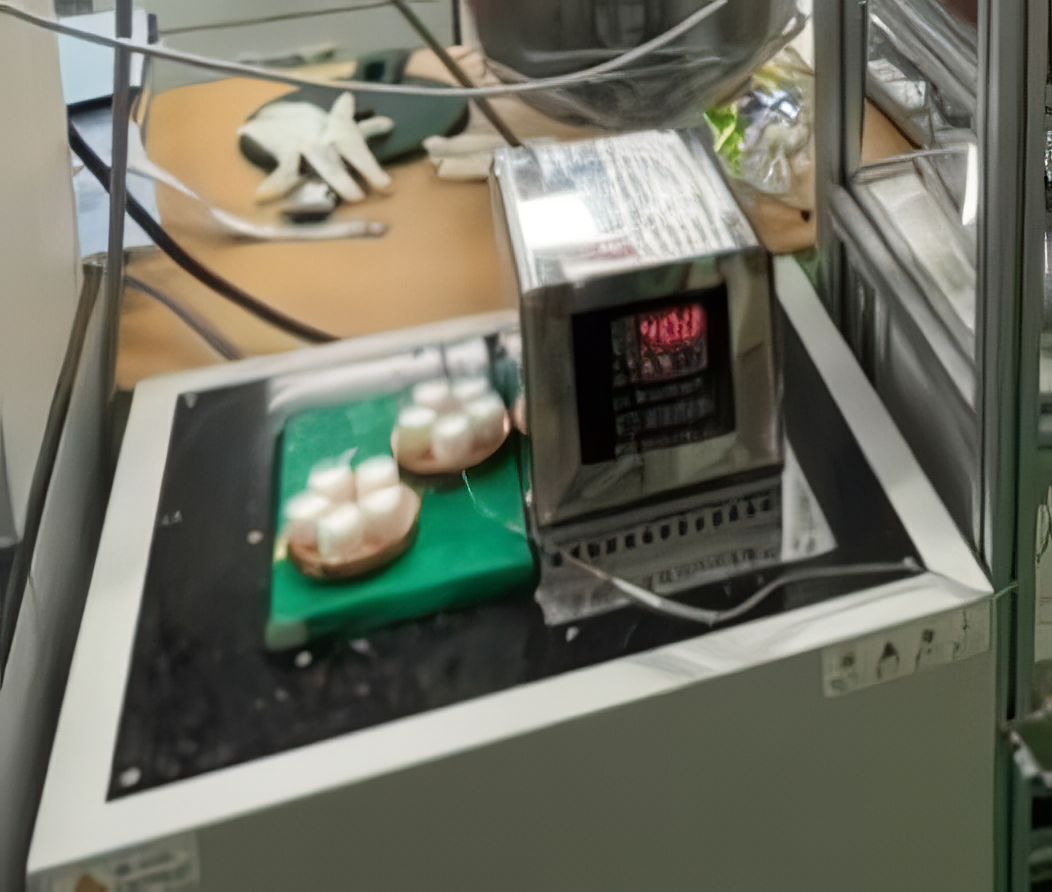

No. 4

By high-temperature vacuum heat treatment

Location

- Room 325, Building 54 (Engineering Hall 4)

Specifications

- Maximum temperature: 2000°C.

Description

- Equipment that heats materials in a sealed chamber where air is removed using a vacuum pump, creating an oxygen- and reactive gas-free environment specialized for preventing oxidation, decarburization, and contamination.

Applications

- Used for sintering materials that require controlled oxidation and other chemical reactions.